1) Simulation with Finite Element Analysis (FEA)

Finite Element Analysis (FEA) as a numerical method is used in engineering applications to simulate the behavior of structures or systems under various loading and conditions.

It is widely employed across different fields like mechanical, civil, aerospace, and biomedical engineering, among others. Manmont utilizes FEA extensively in the design and analysis of pressure and non-pressure containing parts in various components of equipment across different industries, including but not limited to, Oil, Gas, Petrochemical & Energy sectors.

Manmont engineers with more than 15 years solid experience and background in the related field can do FEA for the following equipment as a whole or their related components:

I) Pressure Vessels

FEA helps in assessing the structural integrity and safety of several components and parts of pressure vessels under different operating conditions, including internal pressure, thermal effects, and external loads (including wind and seismic loads). It aids in optimizing the design by evaluating stress distributions, deformation, fatigue life, and potential failure modes.

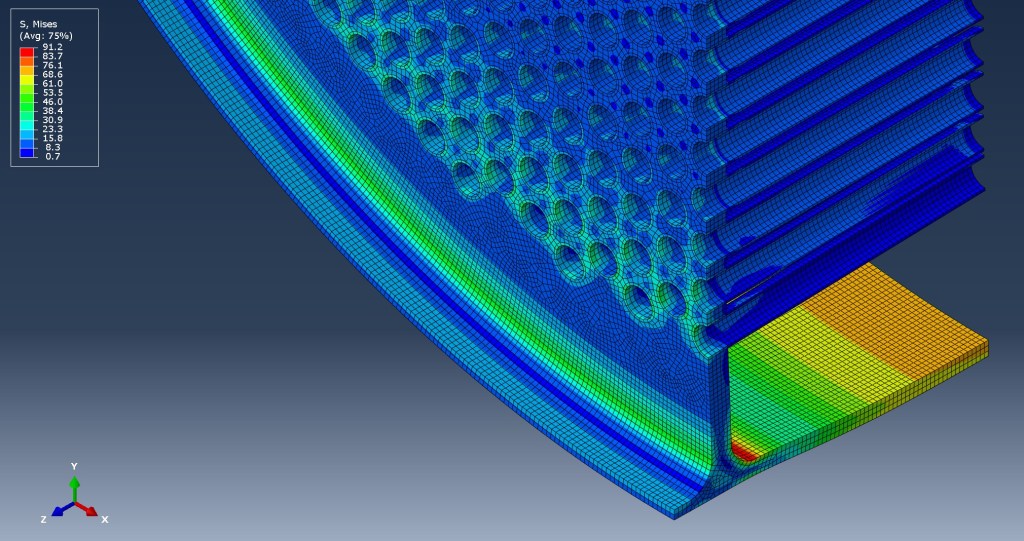

II) Heat Exchangers

FEA is used to simulate the behavior of heat exchanger components, such as tubes, shells, expansion joints, and tubesheets, under various thermal and pressure loadings. It assists in optimizing the design to ensure structural integrity and heat transfer efficiency.

III) Piping Systems

FEA can analyze piping systems subjected to internal pressure, thermal expansion, seismic and wind loads, and other forces. It helps engineers determine stress concentrations, potential failure points, and the effects of different support configurations.

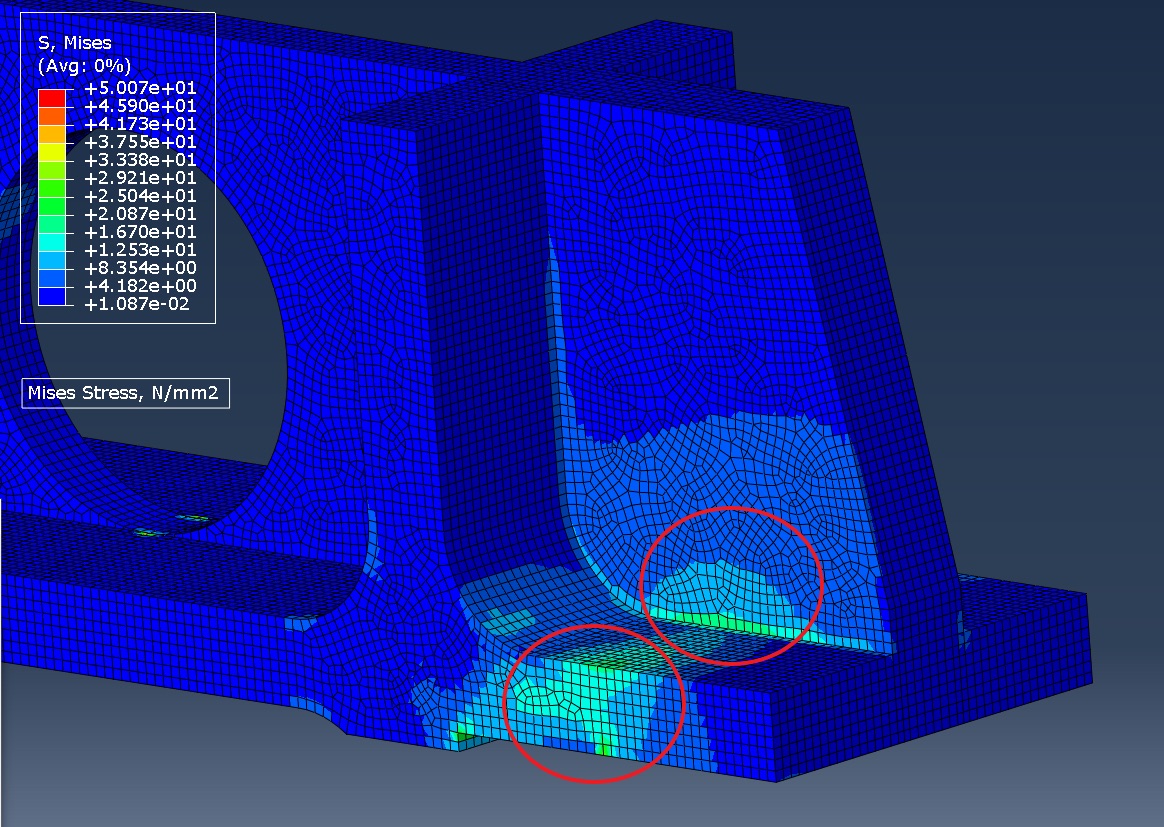

IV) Cast Tubesheets in Fired Heaters & Furnaces

By employing FEA in the design and analysis of cast tubesheets in fired heaters, engineers can make informed decisions regarding material selection, geometry, and operational parameters

Our range of FEA simulation capabilities are:

○ Static vs. Dynamic Analysis

○ Linear vs. Non-Linear Analysis (Elastic, Perfectly Plastic or Elastic-Plastic Analysis)

○ Fatigue Analysis

○ Creep Analysis

○ Buckling Analysis

○ Non-Linear Analysis for Contact Problems

Some FEA Projects done successfully by Manmont engineers:

○ Design verification of piping nozzle load application on rectangular plug type header boxes of air-cooled heat exchanger by linear elastic FEA.

○ Design verification of triple joint forging for attachment of shell, skirt and bottom head of a vertical pressure vessel by linear elastic FEA.

○ Sulphur Condenser tubesheet configuration and thickness verification under thermal and pressure loading by perfectly plastic FEA.

○ Cracking furnace convection coil cast tubesheet geometry and material verification under thermal (in the range of creep) and sustained load by linear fatigue FEA.

○ Fatigue analysis for WHB

○ Buckling analysis of pressure vessel

2) Numerical Simulation(CFD)

Simulation with CFD Analysis

Computational Fluid Dynamics (CFD) analysis is extensively used in various engineering applications such as aerospace, automotive, energy and more. It provides insights into fluid behavior, optimizing designs, and predicting performance without the need for expensive physical prototypes, saving time and resources in the design process.

Computational Fluid Dynamics (CFD) finds widespread applications across various engineering disciplines due to its ability to simulate and analyze fluid flow, heat transfer, combustion and related phenomena.

While numerous commercial CFD codes exist today, enabling engineers with basic engineering knowledge to conduct various analyses, achieving accurate and reliable simulations, along with the comprehensive interpretation of results, demands years of practice and experience in the specific field.

Engineers at Manmont possess extensive expertise across multiple engineering domains such as Oil, Gas & Petrochemical, Energy sector, among others. Their proficiency allows for precise CFD analysis, facilitating design verifications and the development of optimized solutions.

Our range of CFD simulation capabilities are:

○ Single or Multiphase Flows

○ Laminar or Turbulent Flows

○ Incompressible or Compressible Flows

○ Heat Transfer Simulation

○ Combustion Simulation

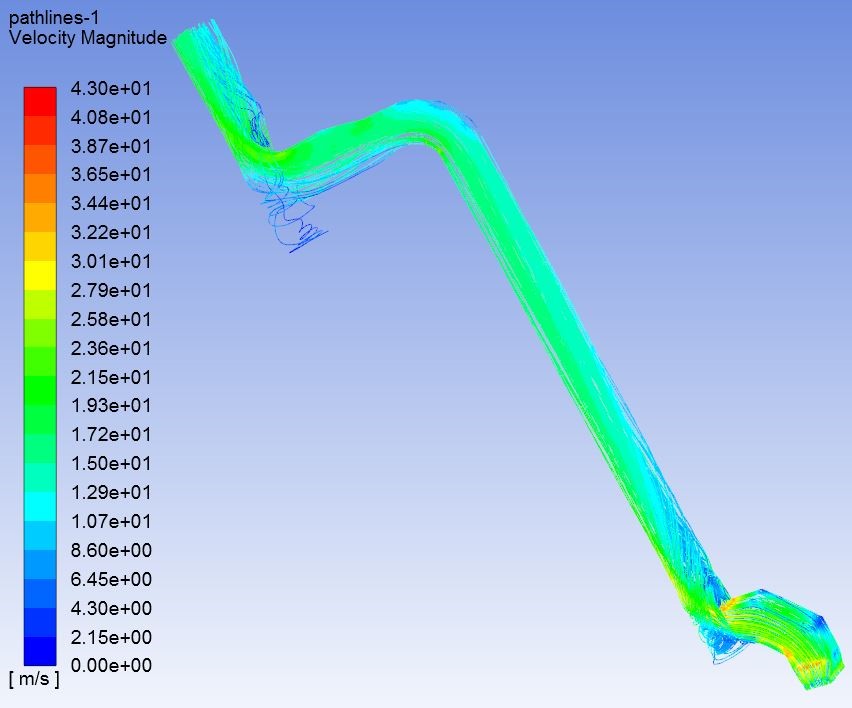

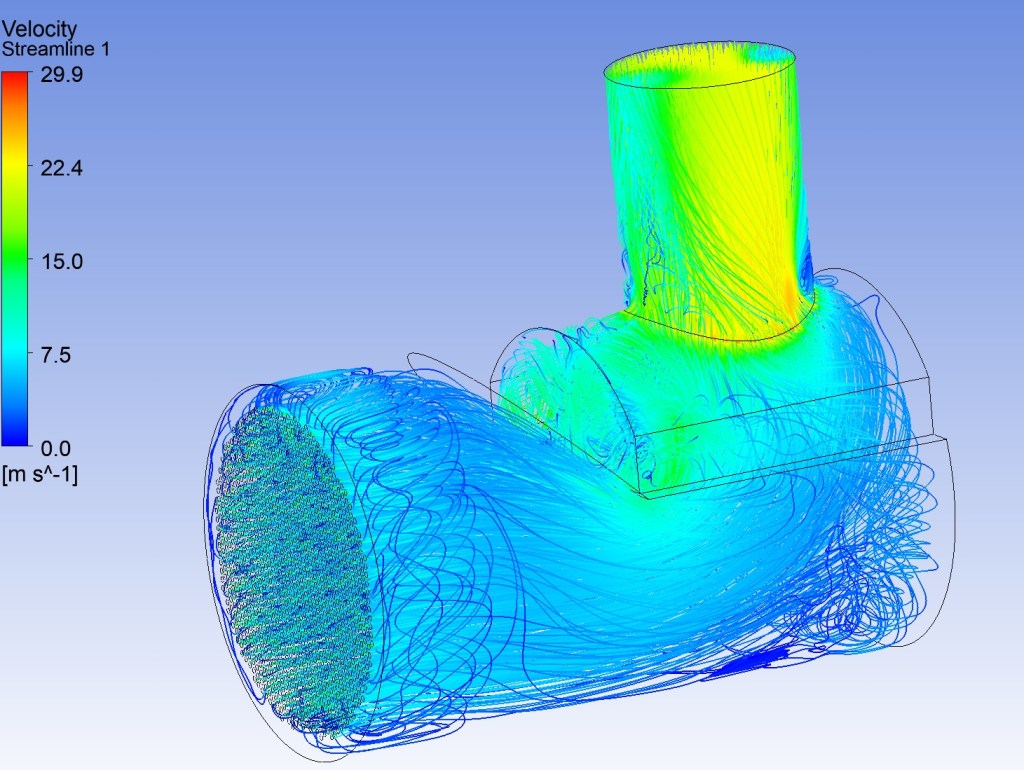

Some CFD Projects done successfully by Manmont engineers:

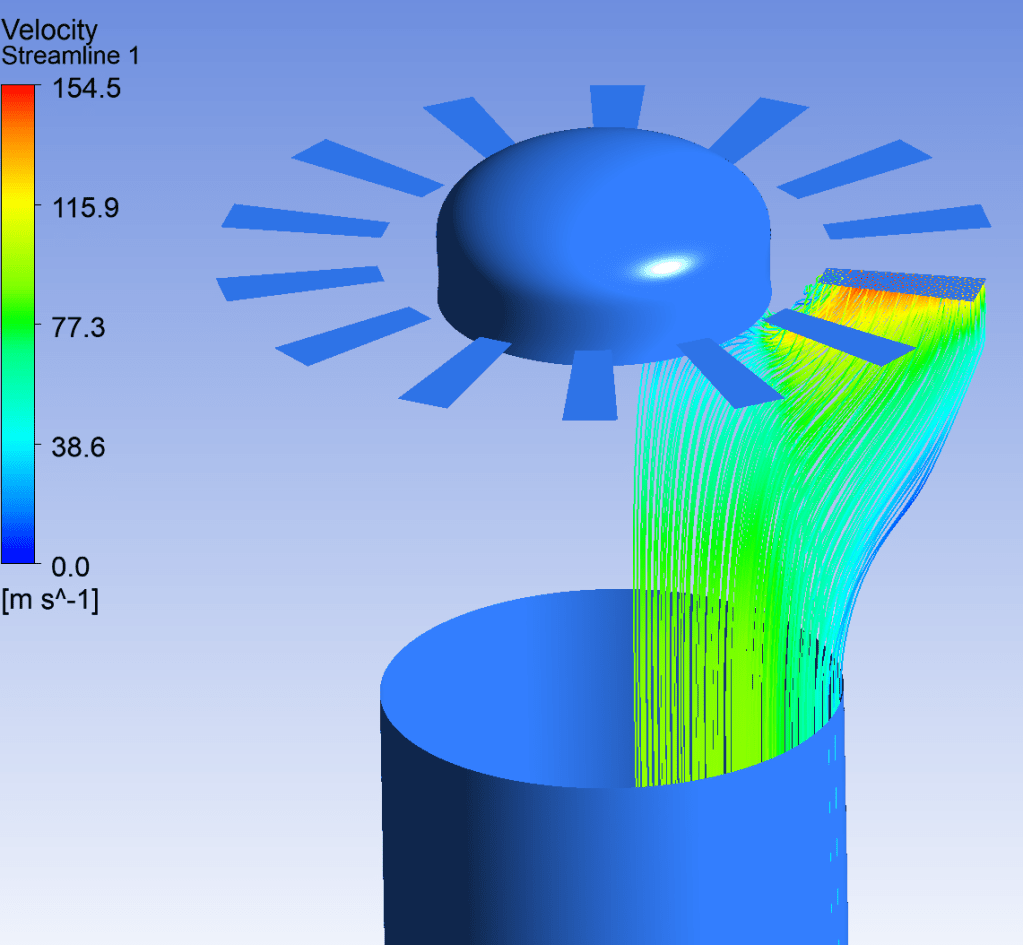

○ Pressure loss calculation for a steam -assisted Flare Tip by Compressible CFD Simulation.

○ Combustion efficiency and soot formation study for an Air-Assisted Flare Tip.

○ Flare liquid seal pressure loss calculation by VOF CFD Simulation.

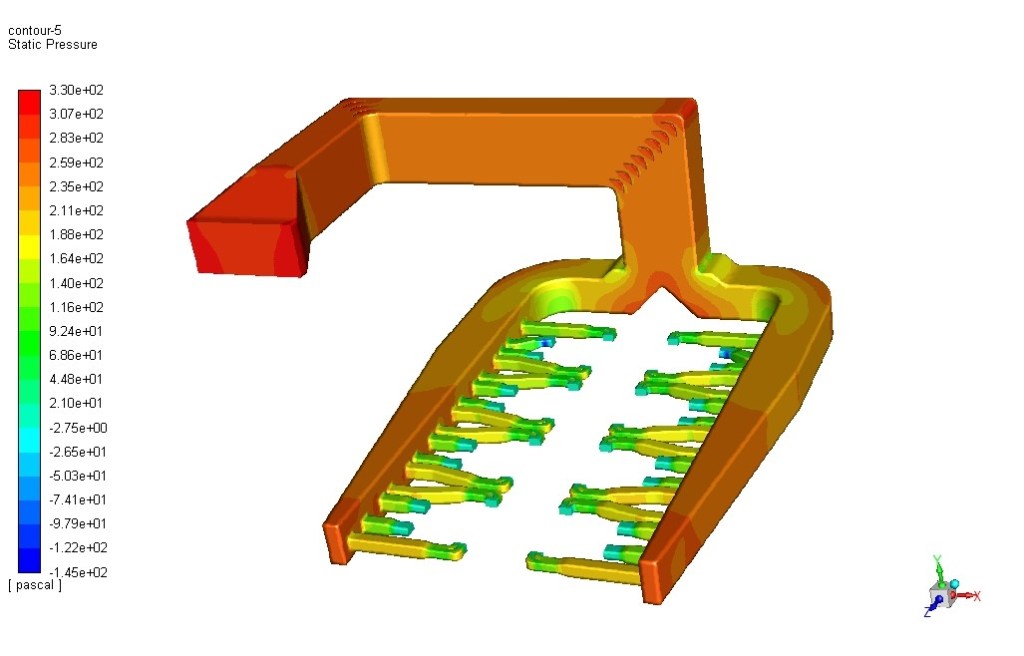

○ Flow field distribution at inlet channel of a Sulphur Condenser.

○ Maldistribution of flow field at inlet of an Air-Cooled Heat Exchanger.

○ Pressure Loss calculation and flow distribution of inlet ducts of a Box-type Fired Heater.

○ Draft calculation inside Fired Box of an Ethane Cracking Furnace.

○ Temperature and Heat Flux distribution within Radiant Coils of an Ethane Cracking Furnace.