Engineering Service for Fired Heaters

Wide Range of Fired Heaters

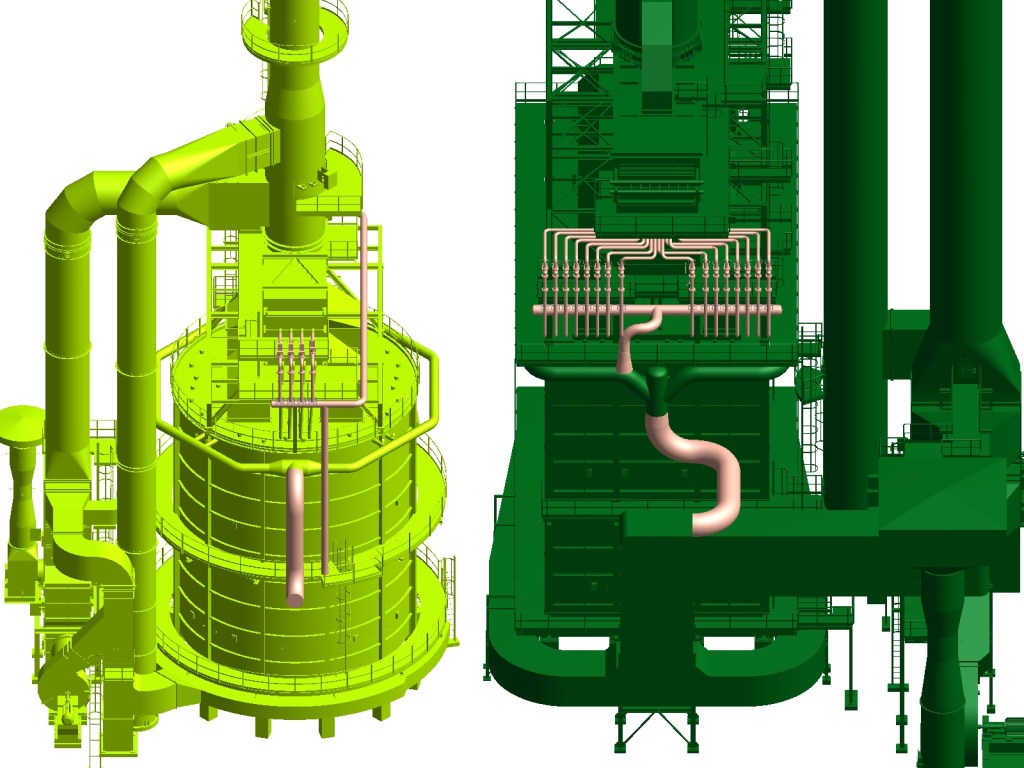

Manmont Engineering specializes in the engineering and design of a wide range of fired heaters used across multiple industrial sectors, including:

Refinery

○ SRU and TGCU (Sulphur Recovery Unit and Tail Gas Clean-Up)

○ Furnaces of all types

○ CO Boilers

○ Waste Processing

○ Gas treating

○ Hydrogen Reformers

Petrochemical

○ Ammonia Reformers

○ Methanol Reformers

○ Cracking Furnaces

Energy Conservation

○ Engineering Studies

○ Waste Heat Recovery Units for several applications including at gas turbines downstream

Manmont Engineering utilises the state-of-the-art technology in the design and engineering of fired heaters used in refineries, chemical and petrochemical plants.

In addition to commercially available software, we also have our own proprietary packages for many specially units. Due to the specific design constraints typical of the different process units, our process design and technologies are divided, accordingly, in the following major applications:

○ Crude Atmospheric Distillation

○ Vacuum Distillation Heater

○ Catalytic Reforming

○ Steam Reforming for Hydrogen manufacturing

○ Visbreaking

○ Cracking Furnace

○ Coking

○ Hydrocracking

[LEARN MORE]

Energy Conservation

The bulk of the energy requirements of the world is presently derived from fossil fuel sources. These sources are getting depleted at a faster rate.

Since alternative sources have not been developed to full extent, conservation of energy has assumed great importance today, in particular when the energy cost is also increasing day by day.

It may be very impressive to note that a refinery with moderate to low furnaces efficiency is firing the equivalent of 4% of the crude if processes and that improvement of efficiency up to 90% may save 0.5% to 1% of total processed crude.

This means, in a 12 MM t/y refinery a saving of more than 100.000 t/y. Following are the factors considered in design and operation of fired heaters to make it more fuel efficient:

I) COMPLETE COMBUSTION WITH MINIMUM EXCESS AIR

II) PERFORMANCE AT TURNDOWN CONDITIONS

III) PROPER HEAT DISTRIBUTION

IV) REDUCING HEAT LOSSES FROM FURNACE OPENINGS

V) PRESSURE CONTROL

VI) MINIMISING WALL LOSSES

VII) WASTE HEAT RECOVERY FROM FURNACE FLUE GASES

[LEARN MORE]

Our Engineering Service

Our comprehensive fired heater engineering services encompass the entire lifecycle of your heating equipment, from initial design and fabrication oversight to ongoing maintenance and optimization.

Our team of dedicated engineers possesses the expertise to tackle any challenge, whether it’s designing a new heater to meet your specific process needs, troubleshooting operational issues, or maximizing efficiency through performance assessments and upgrades.

We are committed to providing a single point of contact and a collaborative approach, ensuring your fired heater operates safely, reliably, and cost-effectively throughout its lifespan.

Following are summary of our services

○ Process & Hydraulics Design

○ PFD & P&ID Development

○ Control Philosophy Development

○ Piping Stress Analysis Piping 3D Modelling

○ Structural Engineering and 3D Modelling

○ Mechanical Engineering

○ Refractory Lining Engineering

○ Electrical & Instrument Engineering